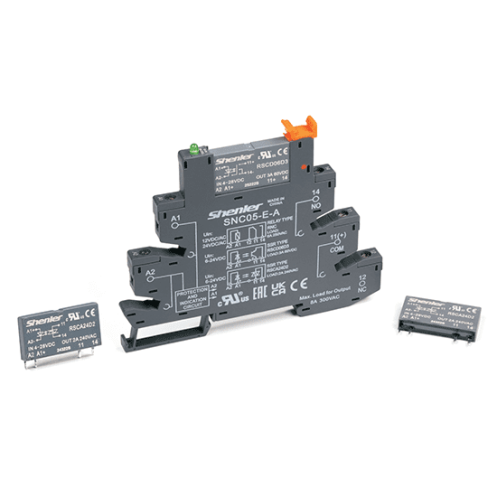

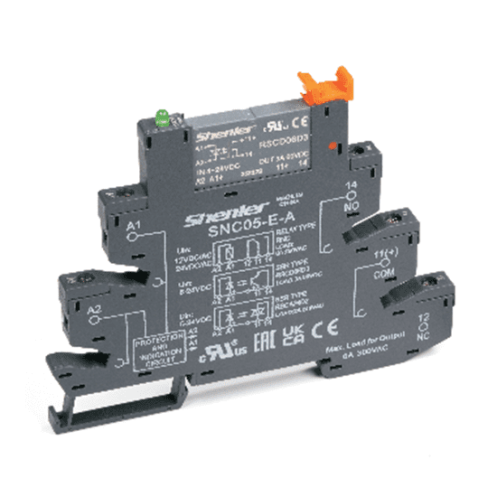

RSC Series Solid State Slim Relay

Features

Ultra thin, small size, fast switching response

no contact, no spark, long service life

NO DC,AC output

MOSFET output for DC, TRIAC output for AC.

Imported optocoupler isolation

Wide supplyDC voltage range

Shenler industrial control relay is widely used in the output signal and safety drive of PLC, CNC system,

robot, intelligent manufacturing and other control systems. It is one ofthe best choices to realize the

automatic assembly line of various equipment and products such as remote control, production and

processing, packaging, transportation, detection and storage.

Share Our Social

RSCA Series:

Series: RSC

Load type: A: ACload

Rated load range: 24 : 240VAC

Control voltage range: D : 4-28VDC 、E:15-28VDC

Rated load current:2:2A

Load current:Blank: Zero voltage switching、R: Random switching

RSCD Series:

Series: RSC

Load type: D: DC load

Rated load voltage: 06:60VDC

Control voltage range: D : 4-28VDC 、E:15-28VDC

Load current:1:1A; 3:3A

RSCA Series:

Product performance:

| Input parameter(Ta=25℃) | |||||||||

| Part No | RSCA24D2 | RSCA24D2R | RSCA24E2 | RSCA24E2R | |||||

| Control voltage range | 4~28VDC | 15~28VDC | |||||||

| Must turn-on voltage | 4VDC | 15VDC | |||||||

| Must turn-off voltage | 1VDC | 5VDC | |||||||

| Control current range | 20mA | ||||||||

| Output parameters(Ta=25℃) | |||||||||

| Part No | RSCA24D2 | RSCA24E2 | RSCA24D2R | RSCA24E2R | |||||

| Rated load voltage | 240VAC | ||||||||

| Load voltage range | 24~280VAC | ||||||||

| Maximum transient voltage | 600VPK | ||||||||

| Load current range | 0.02~2A | ||||||||

| Trigger type | Zero voltage switching | Random switching | |||||||

| Maximum conduction time | Yz cycle | 1ms | |||||||

| Maximum turn-off time | Y2 cycle | Yz cycle | |||||||

| Non-repetitive surge current (within 10ms) | ≤50A | ||||||||

| Maximum off-state leakage current (at rated voltage) | ≤1.5mA | ||||||||

| Maximum on-state voltage drop (at rated current) | ≤1.3V | ||||||||

| Out-of-state voltage index rise rate dv/dt | 200V/us | ||||||||

| Load current safety factor | 40-60% | ||||||||

| Other parameters(Ta=25℃) | |||||||||

| Dielectric withstand voltage(Input /Output,50Hz/60Hz) | 2500VAC | ||||||||

| Insulation resistance(@500VDC) | 1000MΩ | ||||||||

| Operating temperature range | -30℃~+80℃ | ||||||||

| Storage temperature range | -30℃~+100℃ | ||||||||

| Weight | approx.4g | ||||||||

Note:

1.When welding and installing the printed substrate, please complete the welding within 8 seconds at 260℃ welding temperature (no more than 2 seconds for each pin).

2.The positive and negative polarity of input and output shall not be connected wrongly, otherwise it is easy to damage the product.

3.The recommended installation torque for base wiring is 0.5N m.

4.When the ambient temperature of the product is high, please refer to the temperature curve for derating.

RSCD Series:

Product performance:

| Input parameter(Ta=25℃) | |||||||||

| Part No | RSCD06D1 | RSCD06D3 | RSCD06E1 | RSCD06E3 | |||||

| Control voltage range | 4~28VDC | 15~28VDC | |||||||

| Must turn-on voltage | 4VDC | 15VDC | |||||||

| Must turn-off voltage | 1VDC | 5VDC | |||||||

| Control current range | 20mA | ||||||||

| Output parameters(Ta=25℃) | |||||||||

| Part No. | RSCD06D1 | RSCD06E1 | RSCD06D3 | RSCD06E3 | |||||

| Rated load voltage | 60VDC | ||||||||

| Load voltage range | 5~60VDC | ||||||||

| Peak withstand voltage | 100VDC | ||||||||

| oad current range | 0.002~1A | 0.002~3A | |||||||

| Non-repetitive surge current (within 10ms) | 16A | 30A | |||||||

| Maximum on-state voltage drop (at rated current) | ≤1.3V | ≤0.1V | |||||||

| Maximum off-state leakage current (at rated voltage | ≤0.1mA | ||||||||

| Maximum turn-on time | ≤1ms | ||||||||

| Maximum turn-off time | ≤1ms | ||||||||

| Load current safety factor | 40~60% | ||||||||

| Other parameters(Ta=25℃) | |||||||||

| Dielectric withstand voltage (Input /Ou | tput,50Hz/60Hz) 2500VAC | ||||||||

| Insulation resistance(@500VDC) | 1000MΩ | ||||||||

| Operating temperature range | -30℃~+80℃ | ||||||||

| Storage temperature range | -30℃~+100℃ | ||||||||

| Weight | 4g | ||||||||

Note:

1.When welding and installing the printed substrate, please complete the welding within 8 seconds at 260℃ welding temperature (no more than 2 seconds for each pin).

2.The positive and negative polarity of input and output shall not be connected wrongly,otherwise it is easy to damage the product.

3.The recommended installation torque for base wiring is 0.5N m.

4.When the ambient temperature of the product is high, please refer to the temperature curve for derating.

5.When connecting inductive load, be sure to reverse parallel the freewheeling diode at the load end (see the wiring diagram for the specific connection method)!

RSCA Series

Wiringdiagram:

Contact Specification:

RSCD Series

Wiringdiagram:

Contact Specification:

RSCA Series

Dimension(mm):

RSCD Series

Dimension(mm):